Engineering & Production

Custom manufacturing of industrial products

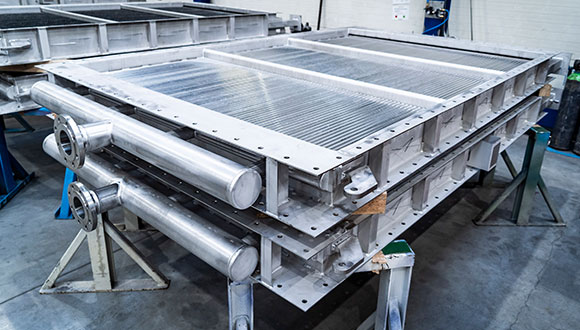

NMH is a custom manufacturing company for industrial products. Our engineering, welding, assembly, and coating services offer various technical solutions. We supply a wide variety of steel, stainless steel or carbon steel products, from single units to complete turnkey machinery installations.

Industrial machinery, constructions, and equipment

Clients such as OEMs (Original Equipment Manufacturers) and engineering or technical R&D companies partner with us for contract manufacturing and mechanical engineering.

Aside from designing, we are experienced with the made-to-measure fabrication of unique machinery parts and constructions as well as prototypes and serial projects. Our clients can be found in branches like production industries, agriculture, recycling, bulk material handling, and offshore.

Our services include design and production engineering, certified welding, assembly, coating, and logistics. The professional NMH production staff and engineers, as well as our management, are situated in one location. Both our business operations and our industrial machinery manufacturing services are certified according to AD 2000-Merkblatt HP0 and ASME VIII Div. I Ed. 2019.

We invite you to get to know us by browsing our website. We would also like to get to know you. Contact NMH at any time to find out how we can assist you with the engineering and production of your advanced industrial products. This way, you can leave the fabrication risks up to us and focus on your design, development, and sales.

German

German Slovak

Slovak